We fight corrosion for the US Navy and industry.

Government Since 2005

WHY OXIFREE?

---

Cost reduction

Costs are reduced in a number of different ways. No advanced preparation is required, applies easily.

Years of protection

Apply Oxifree and the substrate is protected for up to 10 years.

environmentally friendly

Oxifree is made from organic materials and the product contains vegetable oil.

under Water applications

Oxifree products above ground and ti also products items that are under water where the ocean can be harsh on metals.

recyclable

Oxifree can be removed after application then reapplied which adds additional value

Benefits every industry

Power Generation, Oil Refining, Pipeline, Gas & Chemical Processing,Ship Building, Food & Beverage, Gas Transmission, Oil & Gas Drilling, Water Treatment / Desalination, Commercial Building. Aerospace, Pulp & Paper, Pharmaceutical, Storage

VSM Group, LLC.

We are veterans that believe in providing an outstanding product with outstanding service.

SOLUTIONS FOR CORROSION

We Specialize in providing Anti-Corrosion Solutions and Services to all markets including, Military, Oil & Gas, Shipyards and others. we pride ourselves in providing the Best customer service during and after the sale. We have over 30 Years experience in Supply Chain, Consumer Goods, HSE Services, M&E Training, Disaster Relief, Project Management including logistics and all facets of Security.

Our goal is to provide our customers with high quality products and industry best customer service satisfying all your needs in a effective and cost efficient manner.

servicing Multiple industries.

Effectively Saves Money - Year After Year

Customers are the core of our mission

The VSM GROUP STORY

We are a veteran owned business committed to excellence and service. Our focus is on limiting the damage of corrosion in all industries in the US and abroads.

VSM Group, LLC

Our Mission - Stop Corrosion!

Veteran Owned

We are a veteran-owned small business (or VOSB, in government-contracting speak). We are a business that is at least 51% unconditionally owned and controlled by a veteran.

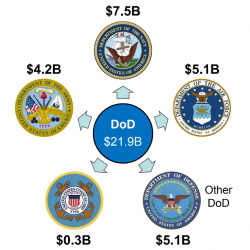

DOD

Almost a decade ago, the Department of Defense laid out plans to protect the machinery, facilities and other assets that were susceptible to corrosion. Today, the budget for this area is nearly 22 Billion US. VSM is committed to helping protect our precious assets from corrosion.

Industries

You should not be surprised to find VSM Group working with the United States Navy. VSM is also working with many other industries including the Oil & Gas, Energy sector. We help companies combat corrosion to valves, flanges, winches, pulleys, bearing housings, pumps, hydraulic systems, steel to concrete interfaces and other equipment in storage. Oxifree & VSM Group are up to the task.

our products

- Minimal preparation required

- Organic, environmentally friendly product

- Easily removed for inspection or NDT inspection through coating

- Can be applied in humid environments

- No shutdown required

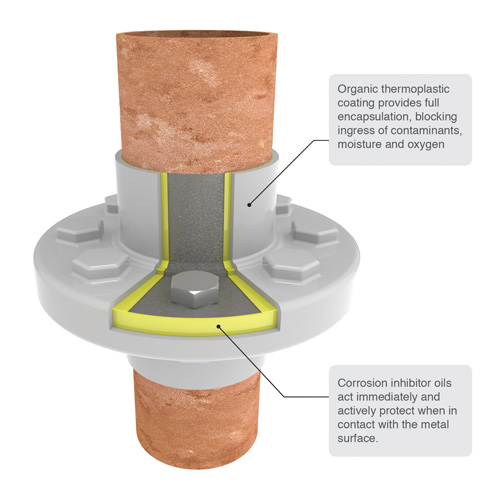

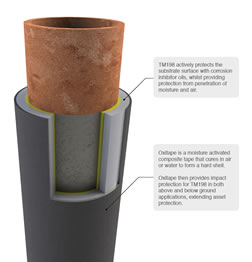

TM198 - Oxifree

TM198 is melted down from a solid resin (in the supply unit) and applied using a heated hose and gun. It provides a organic, pliable thermoplastic barrier coating, which will protect all types of metal components against galvanic pitting and atmospheric corrosion as well as protecting from water and dust ingress.

OXITAPE

Oxitape is a moisture activated composite tape that cures in air or water to form a hard, protective shell which is chemical, UV, abrasion and impact resistant. Oxitape is simply applied over the top of Oxifree TM198 providing a defensive shell that offers complete protection from contact as well as corrosion and contamination. Following the application of TM198, Oxitape can be applied immediately. Typical application time for a flange on a 2 inch pipe is 5 minutes

POLYMELT MACHINE

The Polymelt 12 was designed to offer the following advantages: Ease of transportion Lightweight Compact for use in very confined areas No need for air compressor Multi voltage options Perfect for repairs and gun are all individually heated, therefore no need to flush machine after use

Department Of Defense

U.S.A.

In the USA it is estimated that the annual direct cost of corrosion for the nations industries is hundreds of billions of dollars and managing it is critical to our way of life.

DoD Annual Cost of Corrosion: $21.9B

Read how we are helping the United States Navy protect their fleet from damaging corrosion.

GALLERY (UNSURPASSED PROTECTION)

Maritime

The marine environment is without a doubt the most corrosive where nature takes its toll 365 days a year. Whilst paint coating can provide a reasonable protection to large areas of vessels it is inneffective for protection against corrosion to valves, flanges, winches, pulleys, bearing housings, pumps, hydraulic systems, steel to concrete interfaces and other equipment in storage.

Oxifree has the unique capability of encapsulating these components forming a 100% protective shield which eliminates the harsh corrosive environment destroying these essential spare components. With the increased use of aluminum in military vessels Oxifree can hold the key to eliminating corrosion caused by dissimilar metals.

—–

Energy

From offshore structures to pipelines and refineries, corrosion plagues the oil and gas industry causing the loss of billions of dollars a year in maintenance costs. More importantly, the threatened integrity caused by corrosion opens the door to safety critical issues such as the leakage of toxic gases and chemicals creating a significant liability for a company, not to mention the environmental risks.

Oxifree’s TM198 encapsulation process, using a patented thermoplastic coating with inhibiting oils, has proven successful in the prevention and protection of both new and old surfaces. Because our product is reusable during application, waste is virtually eliminated. Simply collect the excess material, remelt and reuse.

—–

Bases & Facilities

GAO says Naval Shipyards in poor condition, unable to fix ships on time. Navy leaders tell lawmakers one problem is lack of long-term, dependable funding and reliance on Continuing Resolutions.

With longevity being a key factor in the development of Oxifree the Navy can justify the capital investment in Oxifree throughout, ensuring that wherever possible the infrastructure is being protected and ensures longevity with minimal maintenance.

Oxifree protects anything for up to 10 years. It can be removed and reapplied and is extremely cost effective. There are installation all over the world that could benefit from the use of Oxifree.

—-

CONTACT US AND LEARN WHY WE ARE DIFFERENT

10 Year Protection, Save money, Save Time. Contact us to day to find out how!

GET OUR LATEST OFFERS